SLIDE BEARINGS

Our PTFE slide bearings are offered in a range of configurations although each is designed to suit the specific application. A typical slide bearing element consists of 2.5mm thick PTFE (reinforced or virgin PTFE) hot cure factory bonded using our proprietary process to a 3mm thick steel backing plate for welding to the installation. Alternative material thicknesses and grades can be supplied to suit any application. Take a look at our typical configurations for more information.

PTFE slide bearings employ either a reinforced or virgin PTFE at the operating surface. Reinforced PTFE can accommodate loads of 18 MPa (184 kg/cm2) and virgin PTFE can accommodate loads of 7 MPa (71 kg/cm2). The load-bearing capacity of these materials can be increased by containing them in a recessed steel backing plate.

We’ve documented some of our typical configurations for PTFE slide bearings and skidway plates below. We also have expertise in tailoring specifications for bespoke projects.

ASSEMBLY Key

- Reinforced PTFE / Virgin PTFE

- Polished stainless steel plate

- Carbon steel plate / stainless steel plate

- Existing substrate

PTFE SLIDE BEARING – RECESSED

TYPICAL CONFIGURATION

- Top Sliding Plate - 3mm thick polished stainless steel plate.

- Bottom Sliding Plate - 4mm thick Reinforced PTFE / Virgin PTFE bonded into a 2mm deep recess in a 6mm thick carbon steel plate / stainless steel plate.

- Method of Installation - Tack welding, full welding, bolting, mortar embedment.

- Load Capacity - Reinforced PTFE: 50 MPa (510 kg/cm2), Virgin PTFE: 14 MPa (142 kg/cm2).

ASSEMBLY Key

- Reinforced PTFE / Virgin PTFE

- Carbon steel plate / stainless steel plate

- Existing substrate

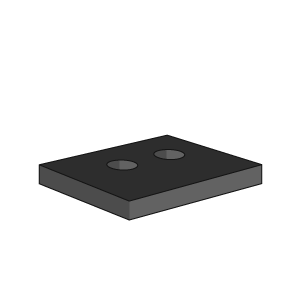

PTFE SLIDE BEARING

TYPICAL CONFIGURATION

- Top Sliding Plate - 2.5mm thick Reinforced PTFE / Virgin PTFE bonded to a 3mm thick carbon steel plate / stainless steel plate.

- Bottom Sliding Plate - 2.5mm thick Reinforced PTFE / Virgin PTFE bonded to a 3mm thick carbon steel plate / stainless steel plate.

- Method of Installation - Tack welding, full welding, bolting, mortar embedment.

- Load Capacity - Reinforced PTFE: 18 MPa (184 kg/cm2), Virgin PTFE: 7 MPa (71 kg/cm2).

ASSEMBLY Key

- Reinforced PTFE / Virgin PTFE

- Polished stainless steel plate

- Carbon steel plate / stainless steel plate

- Existing substrate

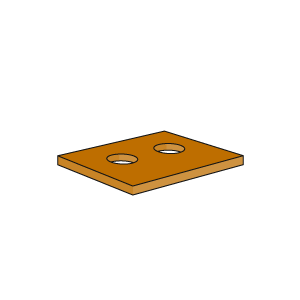

PTFE SLIDE BEARING – BOLTED THRU

TYPICAL CONFIGURATION

- Top Sliding Plate - 2.5mm thick Reinforced PTFE / Virgin PTFE bonded to a 3mm thick carbon steel plate / stainless steel plate.

- Bottom Sliding Plate - 2.5mm thick Reinforced PTFE / Virgin PTFE bonded to a 3mm thick carbon steel plate / stainless steel plate.

- Method of Installation - Bolted through.

- Load Capacity - Reinforced PTFE: 18 MPa (184 kg/cm2), Virgin PTFE: 7 MPa (71 kg/cm2).

Bolted through slide bearings are the most simple for on site assembly. The slots also control the maximum permitted movement.

ASSEMBLY Key

- Reinforced PTFE / Virgin PTFE

- Thermal insulation board

- Carbon steel plate / stainless steel plate

- Existing substrate

PTFE SLIDE BEARING - THERMALLY INSULATED

TYPICAL CONFIGURATION

- Top Sliding Plate - 2.5mm thick Reinforced PTFE / Virgin PTFE bonded to a 3mm thick carbon steel plate / stainless steel plate bonded and mechanically fixed to a 25mm thick thermal insulation board bonded and mechanically fixed to a 3mm thick carbon steel plate / stainless steel plate.

- Bottom Sliding Plate - 2.5mm thick Reinforced PTFE / Virgin PTFE bonded to a 3mm thick carbon steel plate / stainless steel plate.

- Method of Installation - Tack welding, full welding, bolting.

- Load Capacity - Reinforced PTFE: 18 MPa (184 kg/cm2), Virgin PTFE: 7 MPa (71 kg/cm2).

ASSEMBLY Key

- Reinforced PTFE / Virgin PTFE

- Polished stainless steel plate

- Carbon steel plate / stainless steel plate

- Existing substrate

PTFE SLIDE BEARING – COUNTERFACED

TYPICAL CONFIGURATION

- Top Sliding Plate - 3mm thick polished stainless steel plate.

- Bottom Sliding Plate - 2.5mm thick Reinforced PTFE / Virgin PTFE bonded to a 3mm thick carbon steel plate / stainless steel plate.

- Method of Installation - Tack welding, full welding, bolting, mortar embedment.

- Load Capacity - Reinforced PTFE: 18 MPa (184 kg/cm2), Virgin PTFE: 7 MPa (71 kg/cm2).

ASSEMBLY Key

- Reinforced PTFE / Virgin PTFE

- Elastomeric piece

- Carbon steel plate / stainless steel plate

- Existing substrate

PTFE SLIDE BEARING – ELASTOMERIC

TYPICAL CONFIGURATION

- Top Sliding Plate - 2.5mm thick Reinforced PTFE / Virgin PTFE bonded to a 3mm thick carbon steel plate / stainless steel plate.

- Bottom Sliding Plate - 2.5mm thick Reinforced PTFE / Virgin PTFE bonded to a 3mm thick carbon steel plate / stainless steel plate vulcanised to a 6mm thick elastomer sheet vulcanised to a 3mm thick carbon steel plate / stainless steel plate.

- Method of Installation - Tack welding, full welding, bolting, mortar embedment.

- Load Capacity - Reinforced PTFE: 18 MPa (184 kg/cm2), Virgin PTFE: 7 MPa (71 kg/cm2).